The Most Technically Diverse in North America & Toronto

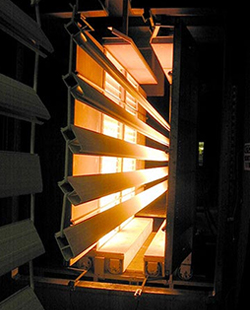

POWDER COATING

- The most technologically advanced powder, liquid coating and Tidal coat facilities in North America & Toronto

- High quality Blasting Services in Toronto

LIQUID COATING

- Plural component coatings

- Tank Lining in Toronto

- Automated Pipe coating for unparalleled quality

TIDAL COAT SERVICE

FABRICATION

- Equipment for blasting coating

- Custom design and fabrication

- Marine corrosion, electrical insulation parts and equipment

- Pipe line corrosion equipment, girth weld coater, automated stripping, blasting and coating

- Transducer tubes

CUSTOMIZED AUTOMATED TIDAL COAT IMMERSION MACHINES

- Water tights door Tidal Coat machines

CONSULTING SERVICES LAYOUT, DESIGN AND TRAINING OF COATING SHOPS

- Coating shop design and best practices outside of the GTA

FIELD STRIPPING, BLASTING AND COATING AND INTEGRITY

- The most advanced and automated field coating equipment

- Environmentally friendly with 1/3 reduction in GHG’s with our integrated spray units

- Efficient and GHG reductions with circulating coatings which arrive on site ready to coat

- Less rutting on the right of ways

- Environmentally friendly automated stripping of PCB’s and asbestos in our yard or in the field

Most highly certified in North America & Toronto

- ISO 9001-2008

- Approved for oil and gas pipe coating, TransCanada, Enbridge, Spectra Energy approved

- Architectural aluminum approved, AMMA 2603,04,05

- U.S. and Canadian Military Approved

- Naval and defence coating

Quality Infrastructure

- Automated state-of-the-art electro-static PLC controlled lines powder applicators ensuring repeatable quality

- Fully automated in both powder and liquid for higher quality and repeatability

- Patents for fusion bond technologies

- Most technically advanced pretreatment

- Separate pretreatment for Aluminum (6 stage AMMA 2605 standard) and Steel (5 stage iron phosphate) for better adhesion

- Automated Fluid bed’s in Toronto

Solid Reputation and Quality Service Toronto

- Unparalleled turn around due to automation

- 70,000 square foot coating plant

- 2 acre laydown area / storage yard

Back