For over 50 years Automatic coating limited has established itself as the premium custom powder coating and Liquid painting job shop in North America, providing a wide range of powder coatings, high performance liquid paints, blasting and Laboratory services to our customers. We are ISO certified, NACE / QP3 and AAMA compliant, as well as being certified by the USA and Canadian Navy.

For over 50 years Automatic coating limited has established itself as the premium custom powder coating and Liquid painting job shop in North America, providing a wide range of powder coatings, high performance liquid paints, blasting and Laboratory services to our customers. We are ISO certified, NACE / QP3 and AAMA compliant, as well as being certified by the USA and Canadian Navy.

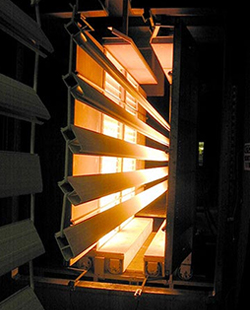

Automatic coating limited have multiple powder coating production lines and batch ovens to provide a wide range of coating services for markets such as Architectural, energy, electrical and general metal finishing as per customers specifications and requirements. Our Flex line can handle parts upto 30 ft long x 8ft high and 5 ft wide on a continuous production line, this line has the ability to run both dedicated architectural aluminum pre-treatment as well as multi stage phosphate wash system for steel. Our PLC controlled automatic powder application guns ensure a consistent and repeatable finish every time, ensuring a high-quality finish that meets and exceeds the customers’ expectations.

We apply a wide range of powder coatings, polyesters, super Durables, acrylics and epoxies for many applications, applied by electrostatic powder coating, hot flocking or Fluidized bed dip coating. Our fluid bed dip systems are some of the largest custom coater fluidized beds in North America, allowing us to encapsulate large items, as well as high build epoxies for the likes of electrical insulation on Bus bars.

Automatic Coating are certified by the major Architectural powder coat suppliers such as Akzo Nobel, Axalta, tiger Drylac, Sherwin Williams and more, for the highest quality levels meeting AAMA 2605 performance and offering warranties upto 30 years on the finished parts. With various batch ovens to handle even larger and heavier items Automatic coating has you covered.

Automatic Coating have a wide array of Sand Blasting / Grit blasting equipment to meet the blasting specifications for high performance powder and liquid coatings being applied. We have both manual blast rooms and automated spinner hangers and plate blasting units. Automatic coating offer steel angular grit as the main blast media for steel, and we utilize nonmetallic blast medias for the likes of Stainless steel, and aluminum, we also have the options to use various abrasives, such as green Diamond, Black Beauty and crushed glass to name a few.

To support the heavy industrial and oil and gas sectors, automatic coating limited have a high-performance liquid paint system, with a 60ft x 30ft x 20 ft blast booth and environmentally controlled spray booth we can offer corrosion protection coatings for large and heavy items upto 16 ft dia x 100 ft long and over 50 tonnes in weight. We offer multiple coating systems for corrosion, high temperature protection and for buried service such as oil and gas pipelines. Automatic coating can provide interior tank linings, pipe linings and chemical vessels, we have developed application equipment to efficiently apply these linings ensuring a uniform porosity free lining for many applications. Automatic coating limited can internally coat pipe sections from 2″ dia and upto 84″ diameter with 100% solids liquid epoxies applied with specialized Plural equipment, certified and approved by the likes of Enbridge oil and gas, TCEnergy and transCanada pipelines. As part of our ongoing dedication to the Pipeline industry we have developed the Pipe Viper systems, these dedicated systems offer on site solutions to stripping old failing coating systems or for the safe and environmentally safe removal of old Asbestos or PCB based coating systems that were used in the past, enabling the utility companies to safely scrap or re-use these pipe sections. After stripping there are Pipe Viper units that will gritblast the pipe to prepare for coating as well as dedicated coating units. These Pipe Viper units allow for a safe and environmentally friendly process in the field, minimizing blast debris and paint overspray in the ditch. To compliment these units, Automatic coating Pipe line services have state of the art field coating rigs, these units are 6×6 drivelines and with on board compressors and generators driven from the trucks PTO to reduce the carbon foot print and be efficient and ready to go at any time. Automatic Pipe Line services can coat straight runs of pipe as well as utilizing skilled and trained technicians to also blast and coat station systems and pipe spools as required.

To support the heavy industrial and oil and gas sectors, automatic coating limited have a high-performance liquid paint system, with a 60ft x 30ft x 20 ft blast booth and environmentally controlled spray booth we can offer corrosion protection coatings for large and heavy items upto 16 ft dia x 100 ft long and over 50 tonnes in weight. We offer multiple coating systems for corrosion, high temperature protection and for buried service such as oil and gas pipelines. Automatic coating can provide interior tank linings, pipe linings and chemical vessels, we have developed application equipment to efficiently apply these linings ensuring a uniform porosity free lining for many applications. Automatic coating limited can internally coat pipe sections from 2″ dia and upto 84″ diameter with 100% solids liquid epoxies applied with specialized Plural equipment, certified and approved by the likes of Enbridge oil and gas, TCEnergy and transCanada pipelines. As part of our ongoing dedication to the Pipeline industry we have developed the Pipe Viper systems, these dedicated systems offer on site solutions to stripping old failing coating systems or for the safe and environmentally safe removal of old Asbestos or PCB based coating systems that were used in the past, enabling the utility companies to safely scrap or re-use these pipe sections. After stripping there are Pipe Viper units that will gritblast the pipe to prepare for coating as well as dedicated coating units. These Pipe Viper units allow for a safe and environmentally friendly process in the field, minimizing blast debris and paint overspray in the ditch. To compliment these units, Automatic coating Pipe line services have state of the art field coating rigs, these units are 6×6 drivelines and with on board compressors and generators driven from the trucks PTO to reduce the carbon foot print and be efficient and ready to go at any time. Automatic Pipe Line services can coat straight runs of pipe as well as utilizing skilled and trained technicians to also blast and coat station systems and pipe spools as required.

Automatic coating limited have also developed our Tidal Coat System in conjunction with the USA and Canadian Navy, offering a patented process to encapsulate metal components and prevent premature corrosion failures out in the ocean. This system is now being deployed globally to fight corrosion and extend the service life of vessels and reducing ongoing maintenance costs.

Part of Automatic Coatings success in industrial corrosion protection coatings is the in-house coating and testing Laboratory. We have NACE certified and fully trained Lab Technicians offering over 25 AST tests in house to ensure all products coated at Automatic Coating Limited meet and exceed the customers requirements and outlast the competition. We work to various industry standards and testing can be performed to meet, ASTM, AAMA, MPTM, NACE, SSPC, QP3 and CSA as well as developing in house testing based on the end use environment the parts will be subjected too. If you have a severe corrosion or chemical application, we have the capability to duplicate that environment, work with our coating suppliers and develop a system than will pass the tests and give the customer peace of mind that the end product will meet its needs.

With Automatic Coatings extensive knowledge of coatings and system we also work closely with our customers to provide custom solutions for fabrication, coatings and project management. Automatic Coating can develop layout, design and training for customers own shops outside of the GTA. We can optimize your production coating operations and share our knowledge to improve work flow and best practices. We have developed state of the art coating systems for customer locations around the world to duplicate our systems in Toronto, ensuring the customer has compatible parts at all locations.

Automatic Coating is a Global leader in Industrial corrosion coatings and protection, customer satisfaction is our priority, with reliable products in a timely manner. We strive to continuously improve both our production and your finished parts and maintain a long-term working relationship.

Back