A quick explanation and examples of how to patch up louvers.View PDF

By Brad Bamford, President, Automatic Coating Limited

I grew up in a family business, founded by my dad in the 1950s. When I was a kid, our shop in Scarborough only had a handful of people and we mainly rewired motors for appliances.

Fast forward 50 years and we’ve perfected many powder and liquid coating techniques we used to apply on household appliances to become a leader in industrial corrosion coating in North America.

Feeling the auto pinch

Automatic Coating now employs 75 people and we supply blasting and coating services to the U.S. and Canadian Navy, nuclear power plants, wind turbine operators, pipeline companies, the mining sector and other industries.

Our business has grown and flourished. But this was not always the case.

Around 2008, several large car manufacturers we worked for began moving their operations to China, Mexico and the southern United States. This was a real blow for our business. We needed to find new clients. That’s when we started working with TransCanada, doing coating work for some of their pipelines.

– See more at: http://www.energyeastpipeline.com/from-bust-to-boom-pipelines-mean-more-jobs/

Louver Patch Kits

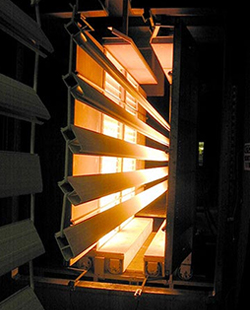

This large parts line compliments ACL’s extensive coating facility

Fluid bed dip up to 24’ long (mil spec) Metal stripping burnoff 5’x 9’x 12’ 9’x 9’x 24’x 10 ton multi oven batch system 6 automated gritblasting wheelabrators of all sizes Indoor loading docks with 10 ton ove

Back