PipeViper Brochure

What Customers Say About Us

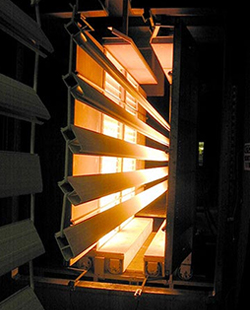

The PipeViper Coating Removal *patent pending*

PipeViper is the only cost effective and portable coating removal system in Toronto that efficiently addresses all environmental and health and safety concerns in removing virtually any existing coating on live or depressurized oil & gas pipelines.

PipeViper is the only cost effective and portable coating removal system in Toronto that efficiently addresses all environmental and health and safety concerns in removing virtually any existing coating on live or depressurized oil & gas pipelines.

This patent pending process removes all coating, cleans the porosity of the pipe, contains and properly bags wastes to meet local environmental standards.

Pipeline Integrity Services Offered

- PipeViper 1 Coating Removal *patent pending*

- PipeViper 2 Abrasive Blasting *patent pending*

- PipeViper 3 Fields Coating Application *patent pending*

- In Shop Coating Application

- Laboratory Testing

When Coatings Start Failing

Traditionally, the most likely corrective action corrosion engineers have at their disposal is to increase the CP current. While this may alleviate some problems with pipeline integrity, it will also have negative side effects, such as:

- Increased risk of coating disbondment

- Increased risk of shielding

- Increased operating costs

- False sense of security

Decisions have to be made whether or not to

- Rehabilitation pipeline

- Replace pipeline

- Combination of both

- Abandon pipeline

PipeViper® System Benefits

- An environmentally safe approach to coating removal.

- Proven track record on efficiencies.

- System is segmented and portable; therefore, easy to move from bell holes.

- Encapsulates coating and debris; therefore, no friable/airborne are present even in asbestos removal operations.

- Allows other trades to work within close proximity; therefore, maximizing overall multi-craft productivity.

- Does not require typical ditch lining.

- Under constant vacuum and all solids are separated through unique filtration.

- Water is recycled for reuse.

- Waste coating residual is processed into bags.

- Provides a high level of surface cleanliness, which enables immediate pipeline integrity inspection to be performed without further cleaning.

Types of Coating Removed

- Coal Tar Epoxy with Asbestos

- Tape Wrap, Single Wrap

- Tape Wrap, Multi-Layered

- Epoxy Paint

- Wax with Paper Wrap

- Asphalt with Stone Guard

- Polyurea – 30+ mil

- Fusion Bond

- PCB (Polychlorinated Biphenyl)

ISO 9001 / AS9100 Aerospace approved coater

Back